Classification/Tag:One-Component/Solvent-Based/Screen & Pad Printing

Features:One-component and at the same time highly resistant glass and metal ink, suitable for screen and pad printing.

Many applications require maximum performance from the printing ink:Good adhesion, dishwasher and cleaning chemical resistance – as a rule, the requirements can only be met by adding a hardener.

Application

Mara® Tech MGO is particularly suitable for glass materials (float and container glass) and metals that require very high chemical and mechanical resistance.

Application Substrates:

Glass for restaurants, cosmetics, and furniture

Sensitive applications, particularly baby bottles

3C applications (touch panels)

Metals, e. g. stainless steel panels

Your Benefits:

One-component baking ink for glass and metal

Cost efficient: No pot life!

Simple, user-friendly handling

Less error potential

Designed for screen and pad printing

Economical stocking

Meets highest demands on adhesion and chemical resistance

Suitable for highly stressed surfaces

200 household dishwasher cycles

Manufacturer approved over 48 h constant climate

Highly resistant against a wide range of cleaners, descaling agents, and foodstuffs

High quality and process safety

Suitable for sensitive applications such as baby bottles

Made without the use of Bisphenol A (BPA)

Successfully tested for applications in line with DIN EN 71/3

Excellent appearance

High opacity

Brilliant colour shades with high gloss

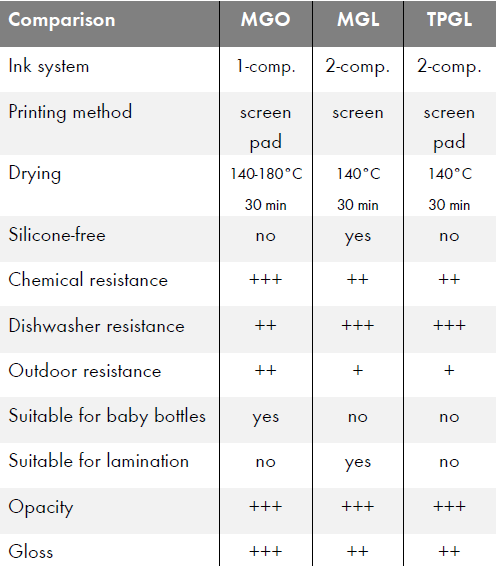

Product Application Image