Classification/Tag:Two-Component/LED-Curable/Screen Printing

Features:UV-LED curable screen printing ink, designed for packaging and indoor restaurant glass, offering rapid curing and scratch resistance.

The time has come for the glass industry to profit from UV-LED technology – with all benefits UV has to offer while excluding UV drawbacks like pre-heating or emissions! In addition, UV-LEDs provide a much longer life span, and energy expenses will drop down below 50%.A modern and sustainable technology.

Application

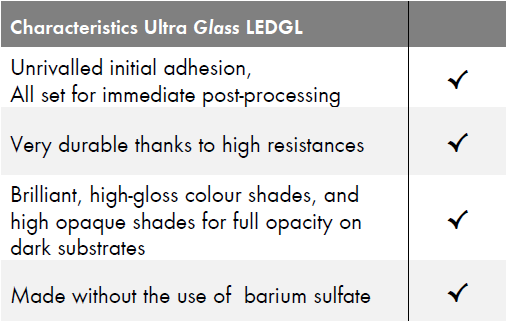

Ultra Glass LEDGL is a UV-LED-curable screen printing ink with excellent properties in terms of initial adhesion, opacity, gloss, and reactivity.

Application Substrates:

Packaging glass, e.g. beverage bottles

Flat glass for indoor use

Cosmetic bottles

Restaurant glass

Glazed ceramics

Metals

Anodized aluminium

Varnished surfaces

PETG

Benefits of UV-LED Curing:

UV-LED lamps are immediately ready for use

No pre-heating necessary, for high outputs

UV-LED units are very compact

Saves space

Only UV-A radiation, causing no ozone emissions

No ventilation necessary

Long lifetime of the UV-LED lamps compared to conventional UV lamps

Requires a minimum amount of Energy

Needs less than 50 % of the energy used for conventional UV curing

UV-LED units contain no mercury

For a safer and more sustainable work and production process

UV-LED does not generate heat

UV-LED inks allow conventional UV, or LED curing without subsequent heat treatment

Flexible printing process

Product Application Image