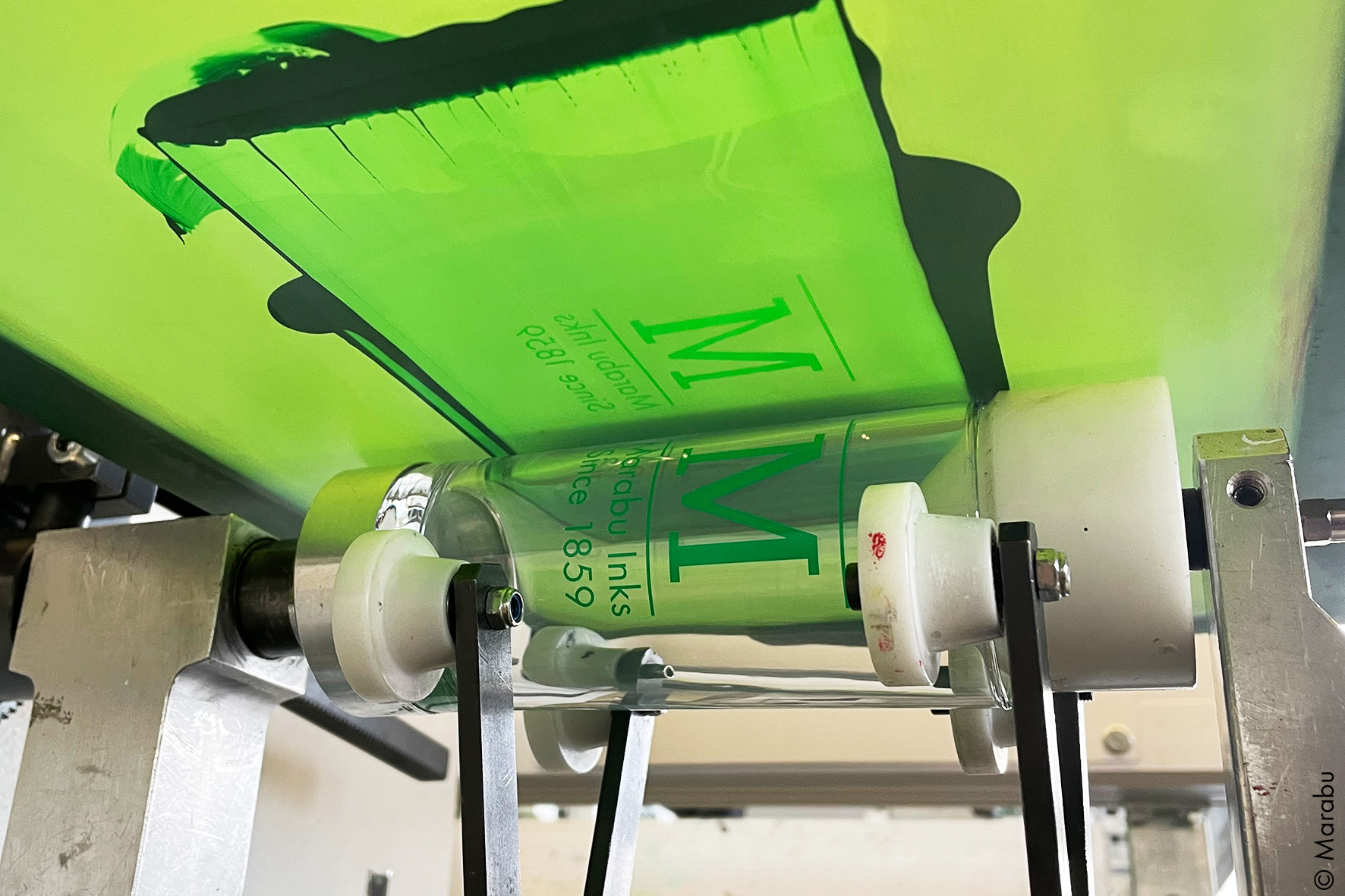

Classification/Tag:Two-Component/UV-Curable/ Screen Printing

Features:UV-curable ink for glass bottles and other glass substrates, offering excellent chemical resistance. UVGL base coat for hot stamping can achieve a metallic effect.

Limited resources and energy efficiency arekeywords often mentioned in the glass sector.Current regulations like the European Directive 94/62 indicate the change from ceramic enamels towards UV curing. Experts agree: In glass printing, UV-curable inks are on the road to success.

Application

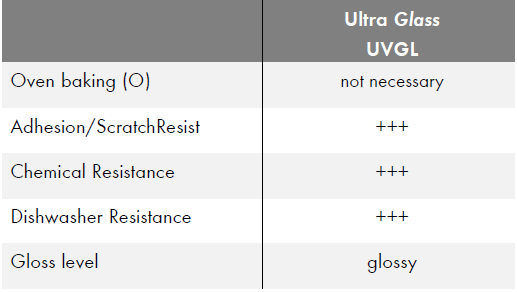

The most important benefit of UVGL: Highest resistances without additional post baking! The economic implications are obvious - the absence of oven drying leads to significant time (seconds vs. hours curing time) and energy savings (not uncommon to reduce by 65%).

Application Substrates

• Restaurant and container glass (drinking glasses and bottles, cosmetic flacons, etc.)

• Large area flat glass for interior decoration (tabletops, cabinet doors, showers, mirrors, gambling machines)

Your Benefits:

No oven baking necessary

→ Considerably reduced energy and investment costs, efficient production through high production speeds, trouble-free handling of large-area substrates

→ Enormous energy, time, and space savings

Highly reactive

→ Efficient production

Formulation without critical heavy metals like lead, or cadmium

→ Environment-friendlier alternative compared to ceramic enamels

→ No legal restrictions concerning the decoration of restaurant/container glass

Very good adhesion, excellent scratch, alkaline, chemical, and dishwasher resistance

→ Universal suitability also for highly stressed restaurant and container glass

Brilliant, glossy colour shades

→ Excellent appearanc

Product Application Image